Saddle Stitch Binding

The printer’s term for stapling

The most economical binding choice

Saddle stitch binding has some disadvantages. One is the limits on thickness of documents using this binding process. Bulkier documents will usually require a different technique. Another snag is that the wire stitches tend to take a toll on the paper, so bear it in mind for articles intended for heavy use. The last notable drawback is that the stitched section becomes the spine, which doesn’t allow for text.

running at full capacity

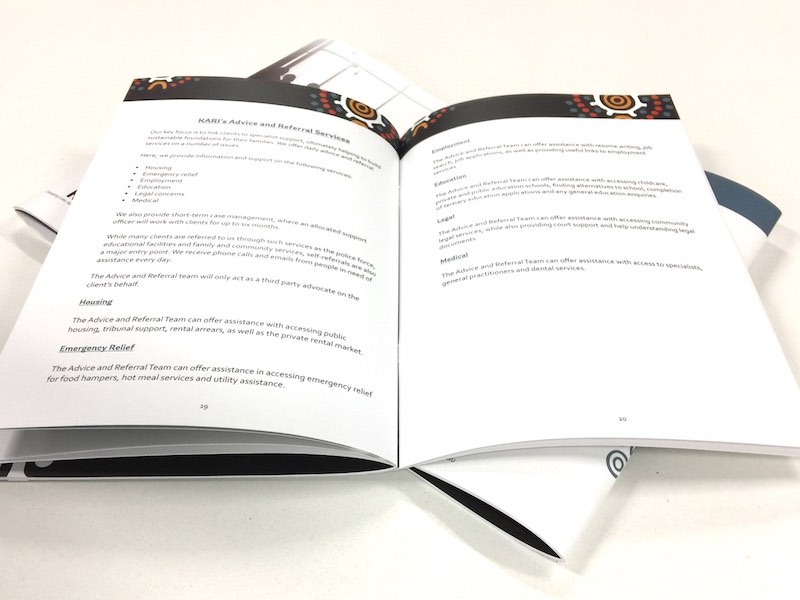

We saddle stitch in-house, so the process of binding magazines or booklets using this method is also quite fast. Our latest booklet making machine (pictured right) collates, or nests, the sheets, then folds them. Next it stitches them, that is, it cuts the wire, forms the staple, drives it through the paper and clinches it from the other side. Finally it trims the booklet. All this is achieved in one pass. Isn’t automation amazing?

Order yours or get a quote today!

If you’d like to know about our other binding styles, you’ll find a summary here.